PRESS BRAKE

CNC Press Brakes

WD67K

The WD67K Series CNC Press Brake boasts all-steel welded, heat-treated constructionwith hydraulic compensation for superior stability, precision, and durability in demandingindustrial applications.

WD67K Series Torsion Bar Two axis CNC Hydraulic Press Brake

WF67K-E

The WF67K-E CNC Press Brake-High-precision, rigid welded structure with stressrelief. 4+1 axis control, stable operation, and mechanical crowning for consistentbending.

WF67K-E Series Hydraulic Synchronous CNC Press Brake

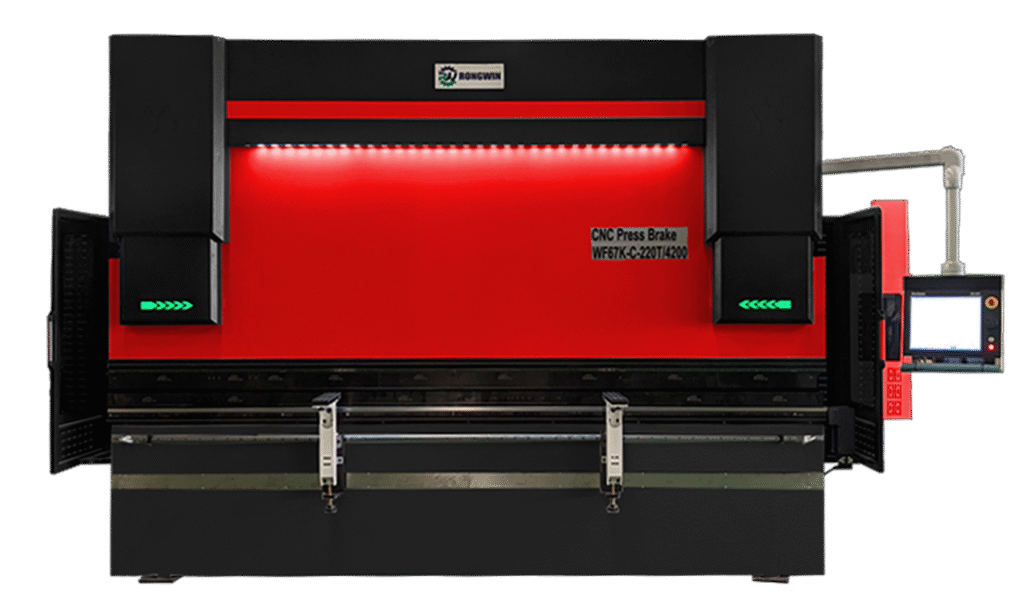

WF67K-C

The WF67K-E CNC Press Brake-High-precision, rigid welded structure with stressrelief. 4+1 axis control, stable operation, and mechanical crowning for consistentbending.

WF67K-C Series Hydraulic Synchronous CNC Press Brake

WF67K-M

The WF67K-M Hybrid CNC Press Brake – No oil pipes, 70% energy savings vs traditional models. Delivers fast speed, high precision, stability & rapid response.

WF67K-M Series Hybrid CNC Press Brake

RW-A

The RW-A Press Brake Robot automates metal bending with +0.1mm precision, 30-50% faster output,and safer operation. Pertect for automotive and aerospace fabrication.

RW-A Series Robot Press Brake

RW03-A

The RW03-A features one-time positioning, multi-sided bending different thicknesses, one mold to complete automatic tool change, automatic avoidance.

RW03-A Series Press Arm Type Panel Bender

RWA02-X

The RW03-A features Smooth panel surface, no punching norholes, suction cup adsorption.

RWA02-X Series Suction Cup Panel Bender

Electric press brake

EP-D

The EP-D Series Full Servo Electric CNC Press Brake – All-electric design ensures high-speed precision, thermal stability, and rigid performance. Ideal for rapid prototyping and high-volume precision production.

EP-D Series Full Servo Electric CNC Press Brake

EP-S

The EP-S full-servo electric pressbrake redefines standards: 80% energy savings, ±0.01mm precision, oil-free maintenance, intelligent control.

EP-S Series Full Servo Electric CNC Press Brake

Hydraulic Press Brakes

WD67Y

The WD67Y Semi-auto bending.+0.1° precision, CE certified. Cost-effective for sheet metal.

WD67Y Series NC TypeHydraulic Press Brake

Press Brake Spare Parts

We have current spare parts and consumables available for you with fast delivery.

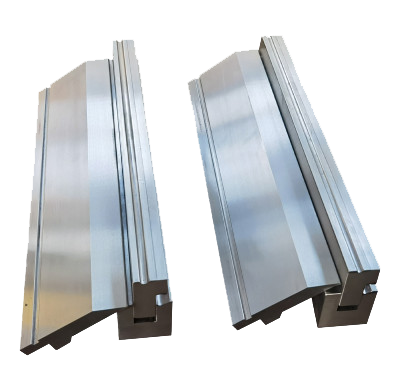

Press Brake Tooling

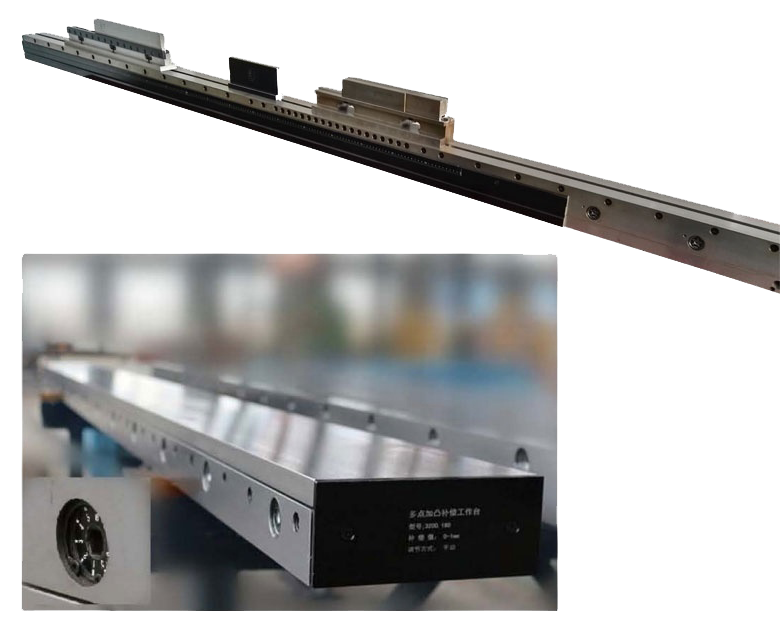

Fast Clamp

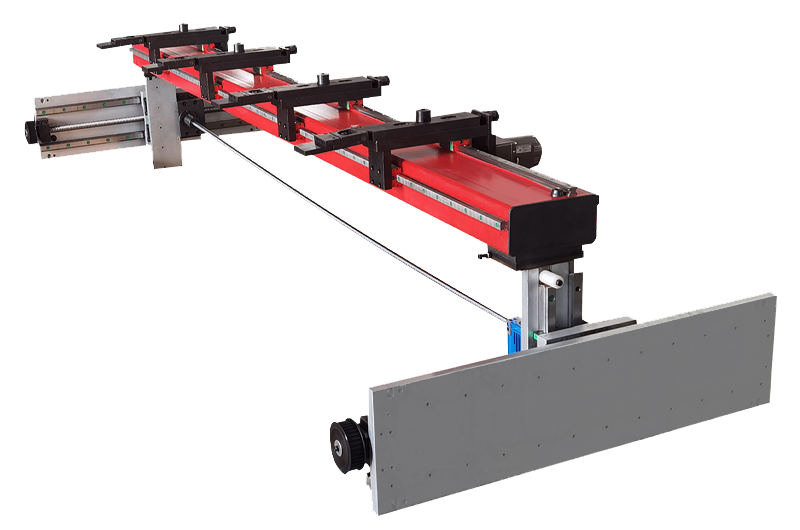

Backguage

Crowing Table

Follower

Our supply chain

FQA

What is Press Brake?

Press brake is to use the equipped mold (general or special mold) to bend the cold metal sheet into various geometric cross-sectional shapes. The press brak can quickly realize the actions of sliding down, jogging, continuous, pressure holding, return stroke and halfway stop, and bend multiple elbows of the same angle or different angles in one feeding.

The press brake generally adopts a special CNC system for the bending machine. The coordinate axis of the bending machine has been changed from a single axis is developed to 12 axes, and the numerical control system can automatically realize the sliding depth control, the left and proper tilt adjustment of the sliding block, the front and back adjustment of the back stopper, the left and right adjustment, the pressure tonnage adjustment and the slider approaching speed adjustment so and on.

What is CNC Press Brake?

The CNC press brake does not need to take special measures during the return (up) trip. In the fast-forward phase of the descending stroke, on the basis of parallel synchronization, two one-way throttle valves are used to eliminate the deviation caused by factors such as manufacturing quality, leakage, etc., and to ensure the downward movement with a certain synchronization accuracy.

When it enters the work advancement stage but has not touched the workpiece, two correction plunger cylinders installed on the workbench are used for further synchronization correction. Imagine that one side first comes into contact with the correction plunger, and the larger correction force slows down or stops the movement of that side until the other side catches up and contacts the correction post hydraulic and pneumatic plugs at the same time. The correction force can be set by the overflow valve and read by the pressure gauge. Practice has shown that the synchronization effect is very obvious, this is because various asynchrony factors can be ignored compared with the correction force. In order to make full use of the capacity of the machine, the overflow valve 3 should be unloaded after a period of time.

What is hydraulic Press Brake?

The Hydraulic Press Brake includes a bracket, a workbench and a clamping plate. The workbench is placed on the bracket. The workbench is composed of a base and a pressure plate. The base is connected to the clamping plate through a hinge. The base is composed of a seat shell, a coil and a cover plate. The coil It is placed in the depression of the seat shell, and the top of the depression is covered with a cover plate.

When in use, the wire is energized to the coil, and after energization, an attractive force is generated on the pressure plate, so as to realize the clamping of the thin plate between the pressure plate and the base. Due to the use of electromagnetic force clamping, the pressure plate can be made into a variety of workpiece requirements, and it can also process workpieces with side walls. Hydraulic press brakes are the safest and more controllable than a mechanical brake. They generally allow for multiple speed settings. Hydraulic also allows for more precision bends, providing greater control when inching down and getting set for a job.

What is Electric Press Brake?

The Electric Press Brake is a high-precision sheet metal fabrication machine driven by servo motors and ball screws. It utilizes digital signals to precisely control the movement of the ram for fast and accurate bending of metal plates. Compared to traditional hydraulic presses, its core advantages include exceptional repeatable positioning accuracy, superior energy efficiency, very low noise and maintenance costs, and a complete absence of hydraulic oil pollution. These features make it particularly suited for high-end manufacturing sectors such as aerospace, new energy vehicles, and electronics, where utmost cleanliness and precision are required, solidifying its role as a key piece of equipment in modern smart factories.