WF67K-E series CNC Press Brake

High-precision, rigid welded structure with stress relief. 4+1 axis control, stable operation, and mechanical crowning for consistent bending.

Ultimate Energy Efficiency

featuring proprietary filling valves and synchronization valve blocks

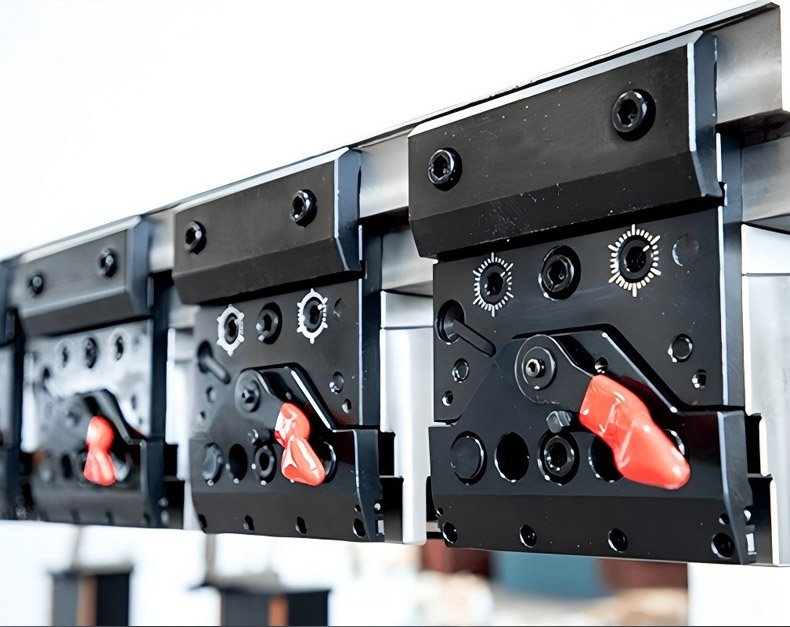

Nanometer-Level Precision

Fixture heightength customizable to workpiece requirements

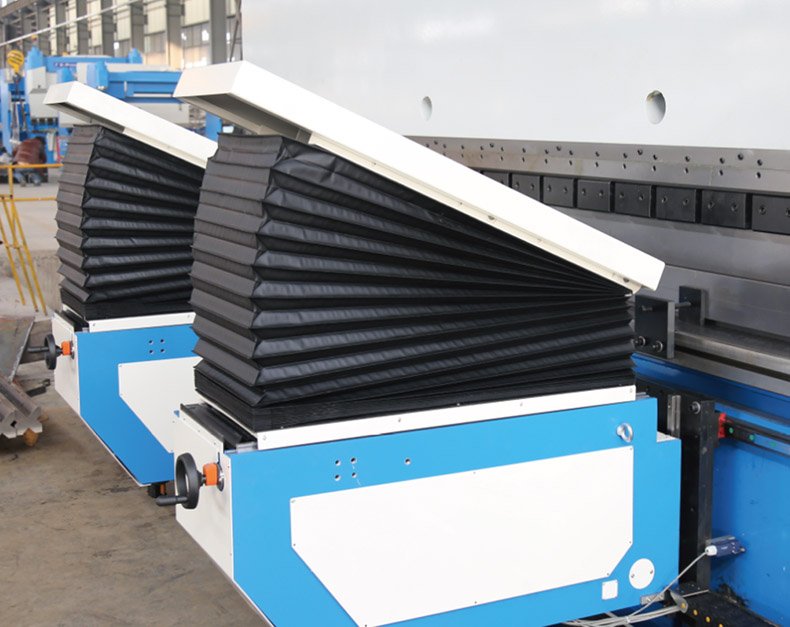

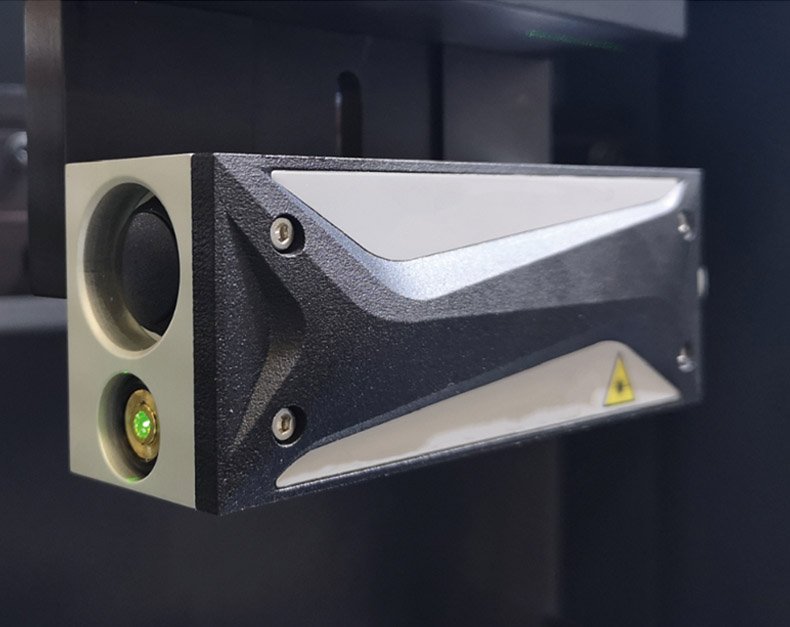

Comprehensive Protection

Ful Enclosure Guard + DSP Laser Protection + Dual-Door Emergency Stop

Standard Equipment

- Schneider Electronic Components

- Yaskawa Servo Driver

- Rexroth Hydraulic Valve

- Germany ECKERLE or VOITH Pump

- INOVANCE Servo Motor

- Spain FORGO Grating Ruler

- Ball Screw + Linear Guide

- Compensation System

- Self Lubricating Ram Guide Plate

- Japan NOK Seal Rings

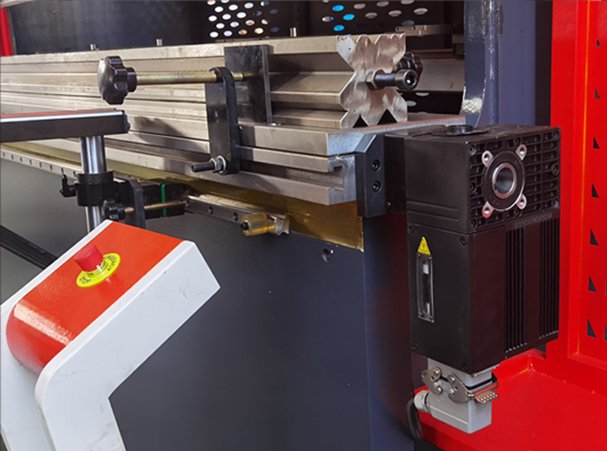

- Backgauge (2 axis : X, R)

6+1 axis performance revolution

- Double linear guide ball screw

- Electric control R axis Zl, Z2 axis

- Effect ofthe electro-hydraulic 6+1 axis.

Ultimate Evolution of Mechanical Compensation

CNC crowning compensates for ram/worktable deformation during bending, significantly improving press brake precision—ideal for high-accuracy stainless steel products.

Safety Equals Profit

- Full Enclosure Guard

- Standard DSP Laser Protection

- Dual-Door Emergency Stop

DA53T Control System

- "Hot-key"touch navigation

- "10.1" high resolution colour TFT

- Crowning control

- Servo and frequency inverter control

- Advanced Y-axis control algorithms

- Profle-T ofine software

- USB memory stick interfacing

Upgrade Solutions

Option Configuration List

Model

WF67K-series

Nominal

Pressure

(mm)

Bending

Length

(mm)

Poles

distance

(mm)

Throat

depth

(mm)

Slipper

Stroke

(mm)

Max

Opening Height

(mm)

Main

motor

(KW)

Travel

(mm)

Weight

(Kg)

Trustworthy Certification

RONGWIN, a globally trusted manufacturer, holds CE and SGS certifications and complies with ISO 9001, ensuring top-tier quality and safety standards.